Autel Maxisys Ultra: Technical Use of Oscilloscope and

Signal Generator Features

The increasing complexity of electronic systems in modern

vehicles has amplified the need for accurate and comprehensive diagnostic

tools. Autel Maxisys Ultra transcends the role of a simple diagnostic scanner,

offering advanced oscilloscope and signal generator features to simplify

vehicle system analysis and diagnostics. This article delves into the technical

applications and advantages of these features.

Oscilloscope Feature and Usage

An oscilloscope is a tool used to visualize electrical

signals. The 4-channel oscilloscope of the Autel Maxisys Ultra enables the

analysis of complex signals and detailed measurements.

Primary Applications:

- Sensor

Diagnostics:

- Analyze

voltage fluctuations from vehicle sensors to verify proper operation.

- For

example, examine the signal waveform of a crankshaft position sensor to

identify synchronization issues.

- Ignition

System Analysis:

- Analyze

the outputs of ignition coils to diagnose potential combustion issues.

- Quick

Troubleshooting:

- Locate

faulty components in complex electrical circuits quickly.

Steps for Use:

- Launch

the Oscilloscope Module:

Select the oscilloscope application from the device software. - Connect

the Probes:

Attach the appropriate probe to the component being tested and select the correct channel. - Adjust

Measurement Parameters:

Set parameters such as voltage range and time base according to the type of signal being analyzed. - Analyze

Live Data:

Examine the signal characteristics through the displayed graphs.

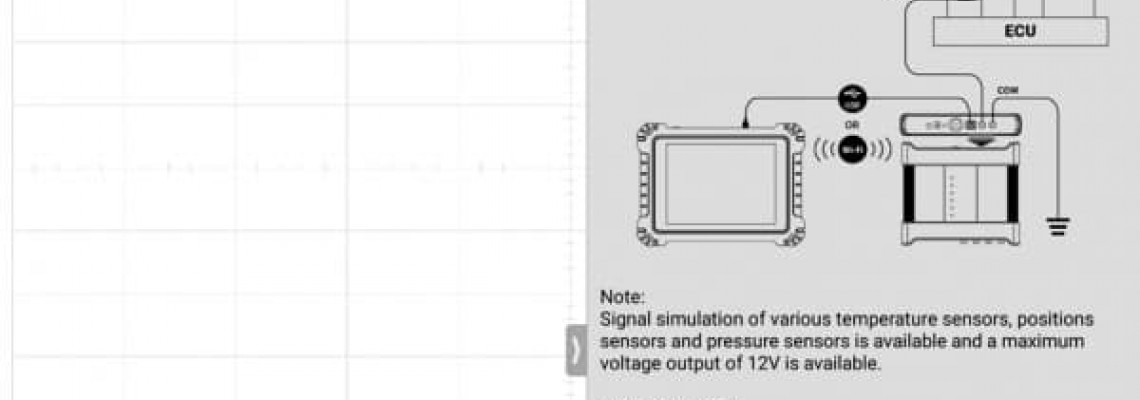

Signal Generator Feature and Usage

A signal generator creates test signals of specific

frequencies and waveforms (e.g., square, sine, or triangular waves). This

feature is especially useful for simulating and testing component

functionality.

Primary Applications:

- ECU

and Module Testing:

Verify ECU response to input signals to ensure proper operation. - Circuit

Validation:

Test vehicle circuits using simulated signals to verify their response. - Actuator

Control:

Send signals to activate components like injectors or fan motors.

Steps for Use:

- Launch

the Signal Generator Module:

Select the signal generator module from the device menu. - Set

Output Type:

Choose from square, sine, or triangular waveforms. - Adjust

Parameters:

Set frequency, voltage, and waveform according to the component being tested. - Conduct

the Test:

Deliver the generated signal to the test circuit or component and observe the response.

Advantages of These Features

- Time

Efficiency: Speeds up the diagnostic process.

- Comprehensive

Analysis: Facilitates in-depth examination of vehicle systems.

- User-Friendly

Interface: The straightforward software is ideal for both experts and

beginners.

Conclusion

The oscilloscope and signal generator features of the Autel

Maxisys Ultra revolutionize professional vehicle maintenance and repair. These

tools enable detailed and reliable analyses, from electrical fault detection to

circuit simulations.

Discover the power of technology in vehicle diagnostics with

Autel Maxisys Ultra!

Practical Example: Crankshaft Position Sensor Testing

Scenario:

The vehicle exhibits irregular vibration during engine

operation, and the Malfunction Indicator Light (MIL) is on. A diagnostic scan

reveals the P0335 - Crankshaft Position Sensor Malfunction code. However, it

remains unclear whether the issue lies with the sensor, wiring, or ECU (Engine

Control Unit).

1. Testing the Crankshaft Position Sensor with an

Oscilloscope:

A crankshaft position sensor detects the position of

rotating engine parts and controls engine timing. If functioning correctly, it

should generate a voltage signal in waveform format.

Steps:

- Step

1: Prepare the Oscilloscope Module

- Launch

the oscilloscope module on the Autel Maxisys Ultra.

- Connect

the probe cables to the sensor’s signal output and vehicle chassis.

- Step

2: Set Parameters

- Set

the voltage range to 0–5V (commonly used by crankshaft sensors).

- Configure

the time base to 10ms/div to match engine RPM.

- Step

3: Analyze Live Data

- Start

the engine and observe the live signal from the sensor.

- A

healthy sensor typically produces a consistent square or sine wave.

Analysis:

- A

regular waveform indicates the sensor is functional.

- If

no signal is observed, the sensor may be faulty, or there could be wiring

issues.

2. Testing the ECU with a Signal Generator:

If the sensor or its signal cannot be verified, testing the

ECU's response to a simulated signal is necessary.

Steps:

- Step

1: Prepare the Signal Generator

- Connect

the signal generator to the crankshaft sensor’s signal wire.

- Set

voltage and frequency parameters, e.g.,:

- Waveform:

Square

- Frequency:

50 Hz (suitable for idle engine speed)

- Voltage:

0–5V

- Step

2: Start Signal Production

- Send

the simulated signal to the ECU.

- Step

3: Verify ECU Response

- Use

a diagnostic tool to observe engine RPM.

- If

the ECU detects and responds to the simulated signal, the issue lies in

the sensor or wiring. If not, the ECU may be defective.

Outcome:

With the Autel Maxisys Ultra, you can:

- Confirm

whether the crankshaft position sensor is functional.

- Verify

ECU response to simulated signals, pinpointing the root cause of the

issue.

These comprehensive analyses prevent unnecessary part

replacements and expedite the troubleshooting process.